3D Printing vs. CNC Machining: What You Should Know

As the world of manufacturing is taken over by computer-guided machines, the process in itself is changing. Furthermore, with technologies like 3D printing and CNC machining, we are no longer limited by hardware power.

This means that small and medium-sized businesses can get bolder in their manufacturing aspirations without relying on suppliers from highly-industrialized countries. However, before you can start a business using any of these technologies, you need to understand how they work and why they are different.

We did the research, and today will discuss the differences and similarities between 3D printing and CNC machining (and why this matters from a business’s perspective).

What are CNC Machining & 3D Printing?

They are both computer-controlled solutions that allow users to make various products, using different materials.

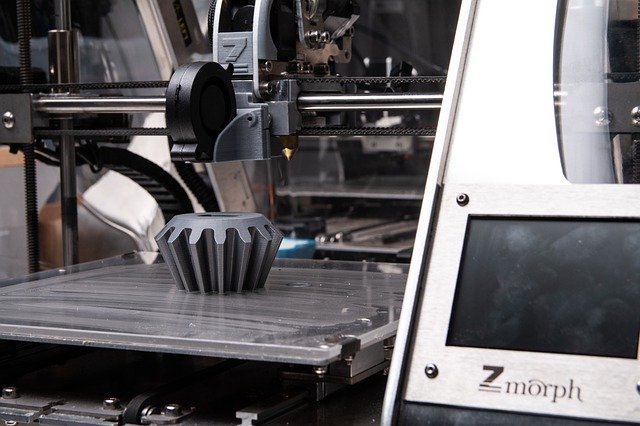

3D printing, also known as additive manufacturing, can build a three-dimensional object from scratch, using a layering technique. There are several different 3D printing technologies and each of them uses different types of materials.

On the other hand, a CNC mill works with a block of solid material (usually wood or aluminum) and shapes it into the desired object. To do so, the machine uses sharp rotating tools to remove bits of material and shape the remaining item according to specifications.

In short, both techniques can be used to create customized objects or prototypes, but the methods are different. With milling, you’re subtracting material, while with printing, you’re adding material.

Why Is This Important?

If we consider the overall cost and energy consumption, it’s rather clear that 3D printing is the more efficient method. The printer is guided to use the optimal quantity of material and requires less energy for the process. On the other hand, CNC machining consumes more energy and produces more waster material.

In this case, it makes a lot more sense to order CNC parts online and use a 3D printer to make the final customizations in-house.

On the other hand, 3D printers only work with a limited selection of materials (depending on the technology they use). Usually, affordable printers work with thermoplastics or raisins, which limits the manufacturing possibilities. CNC machines don’t have this issue as they can work with a wide range of materials (metal alloys, thermoplastics, wood, acrylic, and more).

In the end, the technology you choose depends on your specific needs. If you need to create prototypes that can be tested right away, it’s best to stick with CNC machining. But, if you want to create unique customizations and improve upon existing products, 3D printing is the most efficient choice.

Wrap Up

While it’s easy to think these technologies will revolutionize the manufacturing process, they are not as efficient for mass-production. However, they do have an impact on how small and medium-sized companies adapt manufacturing to their needs.

These machines help reduce a company’s reliance on large suppliers, which can lead to faster results and better customer retention. They can also help with innovation and may lead to the creation of new niches, that wouldn’t exist otherwise.